| Revision as of 23:38, 15 April 2009 editMiami33139 (talk | contribs)6,175 editsm I have removed the despicable whitespace!← Previous edit | Latest revision as of 15:46, 19 January 2025 edit undoMinusBot (talk | contribs)Bots3,739 editsm Proper minus signs and other cleanup. Report bugs, errors, and suggestions at User talk:MinusBotTag: AWB | ||

| (756 intermediate revisions by more than 100 users not shown) | |||

| Line 1: | Line 1: | ||

| {{Short description|Phyllosilicate clay mineral}} | |||

| {{redirect6|Kaolin|the band|Kaolin (band)|the Sailor Moon character|Death Busters#Kaolinite}} | |||

| {{Redirect|Kaolin}} | |||

| {{See also|Aluminium silicate}} | |||

| {{Use dmy dates|date=June 2020}} | |||

| {{Infobox mineral | {{Infobox mineral | ||

| | name = Kaolinite | | name = Kaolinite | ||

| | category = | | category = ] <br />Kaolinite-] | ||

| | boxwidth = |

| boxwidth = | ||

| | image = Kaolinite from Twiggs County in Georgia in USA.jpg | |||

| | boxbgcolor = | |||

| |imagesize=210px| alt = | |||

| | image = KaoliniteUSGOV.jpg | |||

| | |

| caption = | ||

| | formula = {{Chem2|Al2Si2O5(OH)4}}, or in oxide notation: {{Chem2|Al2O3*2SiO2*2H2O}} | |||

| | caption = | |||

| | IMAsymbol = Kln<ref>{{Cite journal|last=Warr|first=L.N.|date=2021|title=IMA–CNMNC approved mineral symbols|journal=Mineralogical Magazine|volume=85|issue=3|pages=291–320|doi=10.1180/mgm.2021.43|bibcode=2021MinM...85..291W|s2cid=235729616|doi-access=free}}</ref> | |||

| | formula = Al<sub>2</sub>Si<sub>2</sub>O<sub>5</sub>(OH)<sub>4</sub> | |||

| | strunz = 9.ED.05 | |||

| | color = White, sometimes red, blue or brown tints from impurities | |||

| | |

| system = ] | ||

| | |

| class = Pedial (1) <br /><small>(same ])</small> | ||

| | |

| symmetry = ''P''1 | ||

| | unit cell = a = 5.13 ], b = 8.89 Å <br />c = 7.25 Å; α = 90° <br />β = 104.5°, γ = 89.8°; Z = 2 | |||

| | cleavage = perfect on {001} | |||

| | color = White to cream, sometimes red, blue or brown tints from impurities and pale-yellow; also often stained various hues, tans and browns being common. | |||

| | fracture = Perfect | |||

| | habit = Rarely as crystals, thin plates or stacked. More commonly as microscopic pseudohexagonal plates and clusters of plates, aggregated into compact, claylike masses. | |||

| | mohs = 2 - 2.5 | |||

| | |

| twinning = | ||

| | cleavage = Perfect on {001} | |||

| | refractive = α 1.553 - 1.565, β 1.559 - 1.569, γ 1.569 - 1.570 | |||

| | |

| fracture = | ||

| | tenacity = Flexible but inelastic | |||

| | pleochroism = | |||

| | |

| mohs = 2–2.5 | ||

| | |

| luster = Pearly to dull earthy | ||

| | refractive = n<sub>α</sub> = 1.553–1.565, <br />n<sub>β</sub> = 1.559–1.569,<br /> n<sub>γ</sub> = 1.569–1.570 | |||

| | melt = | |||

| | opticalprop = Biaxial (–) | |||

| | fusibility = | |||

| | |

| pleochroism = | ||

| | 2V = Measured: 24° to 50°, Calculated: 44° | |||

| | solubility = | |||

| | streak = White | |||

| | references = <ref>http://www.mindat.org/min-2156.html Mindat</ref><ref>http://www.webmineral.com/data/Kaolinite.shtml Webmineral data</ref> | |||

| | gravity = 2.16–2.68 | |||

| }} | |||

| | melt = | |||

| | fusibility = | |||

| | diagnostic = | |||

| | solubility = | |||

| | references =<ref name=Mindat>{{Mindat |id=2156 |name=Kaolinite |access-date=5 August 2009}}</ref><ref name=Webmin>{{WebMineral |url=http://www.webmineral.com/data/Kaolinite.shtml |title=Kaolinite Mineral Data |access-date=5 August 2009}}</ref><ref name=Handbook>{{cite book |title=Handbook of Mineralogy: Silica, silicates |publisher=Mineral Data Publishing |year=1995 |isbn=9780962209734 |veditors=Anthony JW, Bideaux RA, Bladh KW, Nichols MC |location=Tucson, Ariz. |chapter=Kaolinite |oclc=928816381 |display-editors=3 |chapter-url=http://www.handbookofmineralogy.org/pdfs/kaolinite.pdf}}</ref> | |||

| }}'''Kaolinite''' ({{IPAc-en|ˈ|k|eɪ|.|ə|l|ə|ˌ|n|aɪ|t|,_|-|l|ɪ|-}} {{respell|KAY|ə|lə|nyte|,_|-|lih|-}}; also called '''kaolin''')<ref>{{cite Dictionary.com|kaolinite}}</ref><ref>{{Cite dictionary |url=http://www.lexico.com/definition/kaolinite |archive-url=https://web.archive.org/web/20210125021607/https://www.lexico.com/definition/kaolinite |url-status=dead |archive-date=25 January 2021 |title=kaolinite |dictionary=] UK English Dictionary |publisher=]}}</ref><ref>{{cite American Heritage Dictionary|kaolinite}}</ref> is a ], with the chemical composition ]<sub>2</sub>]<sub>2</sub>]<sub>5</sub>(])<sub>4</sub>. It is a layered ], with one ] sheet of silica ({{Chem2|SiO4}}) linked through ] ]s to one ] sheet of ] ({{Chem2|AlO6}}).{{sfnp|Deer|Howie|Zussman|1992}} | |||

| Kaolinite is a soft, earthy, usually white, mineral (dioctahedral phyllosilicate ]), produced by the chemical weathering of ] minerals like ]. It has a low ] and a low ] (1–15 meq/100 g). | |||

| '''Kaolinite''' is a ] with the chemical composition ]<sub>2</sub>]<sub>2</sub>]<sub>5</sub>(])<sub>4</sub>. It is a layered ], with one ] sheet linked through ] ]s to one ] sheet of ] octahedra.<ref>Deer, W.A., Howie, R.A., and Zussman, J. (1992) An introduction to the rock-forming minerals (2nd ed.). Harlow: Longman ISBN 0-582-30094-0.</ref> Rocks that are rich in kaolinite are known as china clay or kaolin. | |||

| Rocks that are rich in kaolinite, and ], are known as '''kaolin''' ({{IPAc-en|ˈ|k|eɪ|.|ə|l|ᵻ|n}}) or '''china clay'''.<ref>{{cite book|url=https://books.google.com/books?id=Jq2rpN-6AccC|title=Economic geology: principles and practice: metals, minerals, coal and hydrocarbons – introduction to formation and sustainable exploitation of mineral deposits|last=Pohl|first=Walter L.|publisher=Wiley-Blackwell|year=2011|isbn=9781444336627|location=Chichester, West Sussex|pages=331|name-list-style=vanc}}</ref> In many parts of the world kaolin is colored pink-orange-red by ], giving it a distinct ] hue. Lower concentrations of iron oxide yield the white, yellow, or light orange colors of kaolin. Alternating lighter and darker layers are sometimes found, as at ] in Georgia, United States. | |||

| The name is derived from Gaoling or Kao-Ling ("High Hill") in ], ], ].<ref>{{cite encyclopedia |last=Schroeder |first=Paul |author=Paul Schroeder |authorlink= |coauthors= |editor= |encyclopedia=New Georgia Encyclopedia |title=Kaolin |url=http://www.georgiaencyclopedia.org/nge/Article.jsp?id=h-1178 |accessdate=2008-08-01 |edition= |date=2003-12-12 |year=2003 |publisher= |volume= |location= |id= |doi= |pages= |quote= }}</ref> Kaolinite was first described as a ] in 1867 for an occurrence in the ] basin of ].<ref></ref> | |||

| Kaolin is an important ] in many industries and applications. Commercial grades of kaolin are supplied and transported as powder, lumps, semi-dried noodle or ]. Global production of kaolin in 2021 was estimated to be 45 million tonnes,<ref>'U.S. Geological Survey, Mineral Commodity Summaries, January 2022' USGS, 2022.</ref> with a total market value of US $4.24 billion.<ref>'Kaolin Market Size, Share & Trends Analysis Report By Application, By Region And Segment Forecasts, 2022 - 2030. Grand View Research, 2022</ref> | |||

| Kaolinite is one of the most common minerals; it is mined, as kaolin, in ], ], ], ], ], ], ], the ], the ], and the ]. | |||

| {{anchor|Etymology|Name}} | |||

| Kaolinite has a low ] and a low ] (1-15 meq/100g.) It is a soft, earthy, usually white mineral (dioctahedral phyllosilicate ]), produced by the chemical weathering of ] ] minerals like ]. In many parts of the world, it is colored pink-orange-red by ], giving it a distinct ] hue. Lighter concentrations yield white, yellow or light orange colours. Alternating layers are sometimes found, as at ] in ], ]. | |||

| ==Names== | |||

| ==Predominance in tropical soils== | |||

| The ] name '']'' was ] in 1727 from ]'s 1712 ] reports on the manufacture of ].<ref>{{OEtymD|kaolin}}</ref> D'Entrecolles was transcribing the ] term {{lang|zh|{{linktext|高嶺土}}}}, now ] as {{translit|zh|gāolǐngtǔ}} in ], taken from the name of the village of Gaoling ("High Ridge") near Ehu in ], now part of ]'s ].<ref name="Schroeder-2018">{{cite encyclopedia |last=Schroeder PA |encyclopedia=] |title=Kaolin |url=http://www.georgiaencyclopedia.org/nge/Article.jsp?id=h-1178 |access-date=14 March 2019 |date=31 July 2018 |type=online }}</ref>{{sfnp|Needham & al.|2004|p=}} The area around the village had become the main source of Jingdezhen's kaolin over the course of the ].{{sfnp|Needham & al.|2004|p=}} The ] suffix '']'' was later added to generalize the name to cover nearly identical minerals from other locations. | |||

| Kaolinite clay occurs in abundance in soils that have formed from the chemical weathering of rocks in hot, moist climates - for example in tropical rainforest areas. Comparing soils along a gradient towards progressively cooler or drier climates, the proportion of kaolonite decreases, while the proportion of other clay minerals such as illite (in cooler climates) or smectite (in drier climates) increases. Such climatically-related differences in clay mineral content are often used to infer changes in climates in the geological past, where ancient soils have been buried and preserved. | |||

| Kaolinite is also occasionally discussed under the ]s '''lithomarge''' and lithomarga from ] {{lang|la|lithomarga}}, a combination of {{lang|la|litho-}} ({{langx|grc|{{linktext|λίθος}}}},{{translit|grc|líthos}}, "stone") and {{lang|la|marga}} ("]"). In more proper modern use, lithomarge now refers specifically to a compacted and massive form of kaolin.<ref>{{Cite web|title=Lithomarge|url=https://www.mindat.org/min-32424.html|access-date=2022-02-23|website=www.mindat.org}}</ref> | |||

| ==Structural transformations== | |||

| Kaolin-type clays undergo a series of phase transformations upon thermal treatment in air at atmospheric pressure. Endothermic dehydroxylation (or alternatively, dehydration) begins at 550-600 °C to produce disordered metakaolin, Al<sub>2</sub>Si<sub>2</sub>O<sub>7</sub>, but continuous hydroxyl loss (-OH) is observed up to 900 °C and has been attributed to gradual oxolation of the metakaolin (Bellotto ''et al.'', 1995). Due to historic disagreement concerning the nature of the metakaolin phase, extensive research has led to general consensus that metakaolin is not a simple mixture of amorphous silica (SiO<sub>2</sub>) and alumina (Al<sub>2</sub>O<sub>3</sub>), but rather a complex amorphous structure that retains some longer-range order (but not strictly crystalline) due to stacking of its hexagonal layers (Bellotto ''et al.'', 1995). | |||

| ==Chemistry== | |||

| 2 Al<sub>2</sub>Si<sub>2</sub>O<sub>5</sub>(OH)<sub>4</sub> —> 2 Al<sub>2</sub>Si<sub>2</sub>O<sub>7</sub> + 4 H<sub>2</sub>O | |||

| ===Notation=== | |||

| The ] for kaolinite as written in ] is {{Chem2|Al2Si2O5(OH)4}},<ref name=Handbook/> however, in ] applications the same formula is typically written in terms of oxides, thus giving {{Chem2|Al2O3*2SiO2*2H2O}}.<ref>{{Cite book|title=Handbook of Inorganic Compounds|vauthors=Perry DL|publisher=Taylor & Francis|year=2011|isbn=9781439814611|edition=2nd|location=Boca Raton|oclc=587104373}}</ref> | |||

| ===Structure=== | |||

| Further heating to 925-950 °C converts metakaolin to a defect aluminuim-silicon spinel, Si<sub>3</sub>Al<sub>4</sub>O<sub>12</sub>, which is sometimes also referred to as a gamma-alumina type structure: | |||

| ] | |||

| Compared with other clay minerals, kaolinite is chemically and structurally simple. It is described as a 1:1 or ''TO'' clay mineral because its crystals consist of stacked ''TO'' layers. Each ''TO'' layer consists of a tetrahedral (''T'') sheet composed of silicon and oxygen ions bonded to an octahedral (''O'') sheet composed of oxygen, aluminium, and hydroxyl ions. The ''T'' sheet is so called because each silicon ion is surrounded by four oxygen ions forming a tetrahedron. The ''O'' sheet is so called because each aluminium ion is surrounded by six oxygen or hydroxyl ions arranged at the corners of an octahedron. The two sheets in each layer are strongly bonded together via shared oxygen ions, while layers are bonded via ] between oxygen on the outer face of the ''T'' sheet of one layer and hydroxyl on the outer face of the ''O'' sheet of the next layer.<ref name="nesse">{{cite book |last1=Nesse |first1=William D. |title=Introduction to mineralogy |date=2000 |publisher=Oxford University Press |location=New York |isbn=9780195106916 |pages=254–255}}</ref> | |||

| <gallery> | |||

| 2 Al<sub>2</sub>Si<sub>2</sub>O<sub>7</sub> —> Si<sub>3</sub>Al<sub>4</sub>O<sub>12</sub> + SiO<sub>2</sub> | |||

| File:Mica T.png|View of the structure of the tetrahedral (''T'') sheet of kaolinite | |||

| File:Mica dO.png|View of the structure of the octahedral (''O'') sheet of kaolinite | |||

| File:Kaolinite crystal structure.png|Kaolinite crystal structure looking along the layers | |||

| </gallery> | |||

| A kaolinite layer has no net electrical charge and so there are no large cations (such as calcium, sodium, or potassium) between layers as with most other clay minerals. This accounts for kaolinite's relatively low ion exchange capacity. The close hydrogen bonding between layers also hinders water molecules from infiltrating between layers, accounting for kaolinite's nonswelling character.<ref name="nesse"/> | |||

| Upon calcination to ~1050 °C, the spinel phase (Si<sub>3</sub>Al<sub>4</sub>O<sub>12</sub>) nucleates and transforms to ], 3 Al<sub>2</sub>O<sub>3</sub> · 2 SiO<sub>2</sub>, and highly crystalline cristobalite, SiO<sub>2</sub>: | |||

| When moistened, the tiny platelike crystals of kaolinite acquire a layer of water molecules that cause crystals to adhere to each other and give kaolin clay its cohesiveness. The bonds are weak enough to allow the plates to slip past each other when the clay is being molded, but strong enough to hold the plates in place and allow the molded clay to retain its shape. When the clay is dried, most of the water molecules are removed, and the plates hydrogen bond directly to each other, so that the dried clay is rigid but still fragile. If the clay is moistened again, it will once more become plastic.<ref>{{cite journal |last1=Breuer |first1=Stephen |title=The chemistry of pottery |journal=Education in Chemistry |date=July 2012 |pages=17–20 |url=https://www.qvevriproject.org/Files/2012.07.00_RSC_Breuer_ChemistryOfPottery.pdf |access-date=8 December 2020}}</ref> | |||

| 3 Si<sub>3</sub>Al<sub>4</sub>O<sub>12</sub> —> 2 Si<sub>2</sub>Al<sub>6</sub>O<sub>13</sub> + 5 SiO<sub>2</sub> | |||

| ===Structural transformations=== | |||

| ==Uses== | |||

| Kaolinite group clays undergo a series of phase transformations upon thermal treatment in air at atmospheric pressure. | |||

| ], ]]] | |||

| Kaolin is used in ]s, ], ], as a ], in ], as a light diffusing material in white incandescent ], and in ]. It is generally the main component in ]. | |||

| ====Milling==== | |||

| It is also used in ] to extend ] (TiO<sub>2</sub>) and modify gloss levels; in ] for semi-reinforcing properties and in adhesives to modify ].<ref> {{cite web|url=http://www.imerys-perfmins.com/kaolin/eu/kaolin.htm |title=Imerys Performance Minerals: Kaolin (China Clay) |accessdate=2008-08-01 }}</ref> | |||

| High-energy milling of kaolin results in the formation of a mechanochemically amorphized phase similar to ], although the properties of this solid are quite different.<ref name="kaol">{{cite journal|vauthors=Kasa E, Szabados M, Baan K, Konya Z, Kukovecz A, Kutus B, Palinko I, Sipos P|year=2021|title=The dissolution kinetics of raw and mechanochemically treated kaolinites in industrial spent liquor – The effect of the physico-chemical properties of the solids|journal=]|volume=203|page=105994|doi=10.1016/j.clay.2021.105994|bibcode=2021ApCS..20305994K |doi-access=free|hdl=21.11116/0000-0008-06AA-2|hdl-access=free}}</ref> The high-energy milling process is highly inefficient and consumes a large amount of energy.<ref>{{cite book |last1=Baláž |first1=Peter |chapter=High-Energy Milling |title=Mechanochemistry in Nanoscience and Minerals Engineering |date=2008 |pages=103–132 |doi=10.1007/978-3-540-74855-7_2|isbn=978-3-540-74854-0 }}</ref> | |||

| ====Drying==== | |||

| The largest use is in the production of paper, including ensuring the gloss on some grades of paper. Commercial grades of kaolin are supplied and transported as dry powder, semi-dry noodle or as liquid ]. | |||

| {{See also|Buell dryer}} | |||

| Below 100 °C, exposure to low humidity air will result in the slow evaporation of any liquid water in the kaolin. At low moisture content the mass can be described ''leather dry'', and at near 0% moisture it is referred to as ''bone dry''. | |||

| Above 100 °C any remaining free water is lost. Above around 400 °C hydroxyl ions (OH<sup>−</sup>) are lost from the kaolinite crystal structure in the form of water: the material cannot now be plasticised by absorbing water.<ref>'Ceramics Are More Than Clay Alone - Raw Materials, Products, Applications' P. Bormans. Cambridge International Science Publishing, 2004. pg. 180</ref> This is irreversible, as are subsequent transformations; this is referred to as ''calcination''. | |||

| A more recent, and more limited, use is as a specially formulated ] applied to especially organic fruits, ]s, and other vegetation to repel or deter ] damage, and at least in the case of apples, to prevent sun scald. A traditional use is to soothe an upset ], similar to the way ]s (and later, humans) in ] originally used it.<ref>http://cogweb.ucla.edu/Abstracts/Diamond_99.html Evolutionary biology: Dirty eating for healthy living by Jared M. Diamond | |||

| </ref> | |||

| ====Metakaolin==== | |||

| Kaolin is or has been used as the active substance in liquid anti-diarrhea medicines such as Kaomagma and ] . Such medicines were changed away from aluminium substances due to a scare over Alzheimer's disease, but have since changed back to compounds containing aluminium as they are most effective. | |||

| Endothermic dehydration of kaolinite begins at 550–600 °C producing disordered ], but continuous ] loss is observed up to {{convert|900|C}}.<ref name="b1">{{cite journal|display-authors=3|vauthors=Bellotto M, Gualtieri A, Artioli G, Clark SM|year=1995|title=Kinetic study of the kaolinite-mullite reaction sequence. Part I: kaolinite dehydroxylation|journal=]|volume=22|issue=4|pages=207–214|bibcode=1995PCM....22..207B|doi=10.1007/BF00202253|s2cid=95897543}}</ref> Although historically there was much disagreement concerning the nature of the metakaolin phase, extensive research has led to a general consensus that metakaolin is not a simple mixture of amorphous silica ({{Chem2|SiO2}}) and alumina ({{Chem2|Al2O3}}), but rather a complex amorphous structure that retains some longer-range order (but not ]) due to stacking of its hexagonal layers.<ref name=b1/> | |||

| :<chem>Al2Si2O5(OH)4 -> Al2Si2O7 + 2 H2O</chem> | |||

| ====Spinel==== | |||

| In April 2008, the ] announced the successful use of a Kaolinite-derived ] ] infusion in traditional ] known commercially as QuikClot Combat Gauze.<ref></ref> <ref></ref> | |||

| Further heating to 925–950 °C converts metakaolin to an aluminium-silicon ] which is sometimes also referred to as a gamma-alumina type structure: | |||

| :<chem>2 Al2Si2O7 -> Si3Al4O12 + SiO2</chem> | |||

| ====Platelet mullite==== | |||

| ==Miscellany== | |||

| Upon calcination above 1050 °C, the spinel phase nucleates and transforms to ] and highly crystalline ]: | |||

| ], constructed in a used kaolin pit]] | |||

| :<chem>3 Si3Al4O12 -> 2 (3 Al2O3 . 2 SiO2) + 5 SiO2</chem> | |||

| ====Needle mullite==== | |||

| *The ] of kaolinite played a role in ]'s work on the nature of the ]. | |||

| Finally, at 1400 °C the "needle" form of ] appears, offering substantial increases in structural strength and heat resistance. This is a structural but not chemical transformation. See ] for more information on this form. | |||

| ==Occurrence== | |||

| *Kaolinite can contain very small traces of ] and ], and is therefore useful in ]. While a single magazine made using kaolin does not contain enough ] material to be detected by a security-oriented monitor, this does result in truckloads of high end glossy paper occasionally tripping an overly-sensitive ]. | |||

| ] | |||

| Kaolinite is one of the most common minerals; it is mined, as kaolin, in ], ], ], ], ], ], ], ], ], ], ], ], ], ], ], ], ] and ].<ref name=Mindat/> | |||

| Mantles of kaolinite are common in Western and Northern Europe. The ages of these mantles are ] to Early Cenozoic.<ref>{{cite journal|author-link=Piotr Migoń|author-link2=Karna Lidmar-Bergström|vauthors=Migoń P, Lidmar-Bergström K|date=2002|title=Deep weathering through time in central and northwestern Europe: problems of dating and interpretation of geological record|journal=Catena|volume=49|issue=1–2|pages=25–40|doi=10.1016/S0341-8162(02)00015-2|bibcode=2002Caten..49...25M }}</ref> | |||

| *The ], a large ] complex near ], ], ], is constructed in a disused kaolin pit. | |||

| Kaolinite clay occurs in abundance in ]s that have formed from the chemical ] of rocks in hot, moist ]s; for example in ] areas. Comparing soils along a gradient towards progressively cooler or drier climates, the proportion of kaolinite decreases, while the proportion of other clay minerals such as ] (in cooler climates) or ] (in drier climates) increases. Such climatically related differences in clay mineral content are often used to infer changes in climates in the geological past, where ancient soils have been buried and preserved.<ref>{{Cite journal|date=2000-02-01|title=Unraveling climatic changes from intraprofile variation in oxygen and hydrogen isotopic composition of goethite and kaolinite in laterites: an integrated study from Yaou, French Guiana|url=https://www.sciencedirect.com/science/article/abs/pii/S0016703799002999|journal=Geochimica et Cosmochimica Acta|language=en|volume=64|issue=3|pages=409–426|doi=10.1016/S0016-7037(99)00299-9|issn=0016-7037|last1=Girard|first1=Jean-Pierre|last2=Freyssinet|first2=Philippe|last3=Chazot|first3=Gilles|bibcode=2000GeCoA..64..409G}}</ref> | |||

| *], a small town in the state of ] in the United States holds an annual kaolin festival. Sandersville has huge kaolin deposits throughout the town and the surrounding areas, and the kaolin industry is the economic backbone of the region. | |||

| ] | |||

| *When heated to between 650°C and 900°C kaolinite dehydroxylates to form ]. According to the American National Precast Concrete Association this is a ] (SCM). When added to a concrete mix, Metakaolin affects the acceleration of ] hydration when replacing Portland cement by 20 percent by weight. | |||

| In the '']'' (INEAC) classification system, soils in which the clay fraction is predominantly kaolinite are called ''kaolisol'' (from kaolin and soil).<ref>{{cite book|title=Tropical soils and soil survey|last=Young|first=Anthony|publisher=CUP Archive|year=1980|isbn=9780521297684|series=Cambridge Geographical Studies|volume=9|pages=132|name-list-style=vanc}}</ref> | |||

| In the United States, the main kaolin deposits are found in central ], on a stretch of the ] between ] and ]. This area of thirteen counties is called the "white gold" belt; ] is known as the "Kaolin Capital of the World" due to its abundance of kaolin.<ref name="sandersville-ga">{{cite web|url=http://www.sandersville.net/KaolinCapitaloftheWorld.cfm|title=Kaolin Capital of the World|website=City of Sandersville, GA|access-date=27 August 2018}}</ref><ref name="bitter-southerner">{{cite web|url=http://bittersoutherner.com/eat-white-dirt/|title=Making Peace With the Age-Old Practice of Eating White Dirt|last=Reece C|website=The Bitter Southerner|access-date=27 August 2018}}</ref><ref>{{cite news |last1=Smothers |first1=Ronald |title=White George clay turns into cash |url=https://www.nytimes.com/1987/12/12/us/white-georgia-clay-turns-into-cash.html |access-date=19 January 2021 |work=The New York Times |date=12 December 1987}}</ref> In the late 1800s, an active kaolin surface-mining industry existed in the extreme southeast corner of Pennsylvania, near the towns of ] and ], and in what is present-day White Clay Creek Preserve. The product was brought by train to ], on the ] line, along which can still be seen many open-pit clay mines. The deposits were formed between the late ] and early ], about 100 to 45 million years ago, in sediments derived from weathered ] and metakaolin rocks.<ref name="Schroeder-2018" /> Kaolin production in the United States during 2011 was 5.5 million tons.<ref>{{cite tech report|last=Virta R|title=Mineral Commodity Summaries|institution=U.S. Geological Survey|pages=44–45|year=2012|url=http://minerals.usgs.gov/minerals/pubs/commodity/clays/mcs-2012-clays.pdf}}</ref> | |||

| *Ceramists, or more commonly potters, typically think of materials in terms of oxides, thus they write the formula for kaolinite as:<p>Al<sub>2</sub>O<sub>3</sub> ▪ 2(SiO<sub>2</sub>) ▪ 2(H<sub>2</sub>O)<p>This format is also useful for describing the firing process of clay as the kaolin loses the 2 water molecules, termed the chemical water, when fired to a high enough temperature. This is different than clay's physical water which will be lost simply due to evaporation and is not a part of the chemical formula. | |||

| ] in the UK, which is used to dry processed kaolin]] | |||

| During the ] sediments deposited in the ] area of ] were enriched with kaolinite from a ] source due to ].<ref>{{cite journal|display-authors=3|vauthors=Adatte T, Khozyem H, Spangenberg JE, Samant B, Keller G|year=2014|title=Response of terrestrial environment to the Paleocene-Eocene Thermal Maximum (PETM), new insights from India and NE Spain|url=https://www.researchgate.net/publication/263430375|journal=Rendiconti Online della Società Geologica Italiana|volume=31|pages=5–6|doi=10.3301/ROL.2014.17}}</ref> | |||

| ==Synthesis and genesis== | |||

| Difficulties are encountered when trying to explain kaolinite formation under atmospheric conditions by extrapolation of thermodynamic data from the more successful high-temperature syntheses.<ref>{{Cite book|url=https://core.ac.uk/display/29380966|title=Relative stabilities of soil minerals|vauthors=Meijer EL, van der Plas L|publisher=Veenman|year=1980|series=Mededelingen Landbouwhogeschool Wageningen|volume=80|location=Wageningen|pages=18}}</ref> La Iglesia and Van Oosterwijk-Gastuche (1978)<ref>{{Cite journal|vauthors=La Iglesia A, Van Oosterwyck-Gastuche MC|date=1978|title=Kaolinite Synthesis. I. Crystallization Conditions at Low Temperatures and Calculation of Thermodynamic Equilibria. Application to Laboratory and Field Observations|journal=Clays and Clay Minerals|volume=26|issue=6|pages=397–408|doi=10.1346/CCMN.1978.0260603|bibcode=1978CCM....26..397L|doi-access=free}}</ref> thought that the conditions under which kaolinite will nucleate can be deduced from stability diagrams, based as they are on dissolution data. Because of a lack of convincing results in their own experiments, La Iglesia and Van Oosterwijk-Gastuche (1978) had to conclude, however, that there were other, still unknown, factors involved in the low-temperature nucleation of kaolinite. Because of the observed very slow crystallization rates of kaolinite from solution at room temperature Fripiat and Herbillon (1971) postulated the existence of high activation energies in the low-temperature nucleation of kaolinite. | |||

| At high temperatures, ] thermodynamic models appear to be satisfactory for the description of kaolinite dissolution and ], because the thermal energy suffices to overcome the ]s involved in the ] process. The importance of syntheses at ambient temperature and atmospheric pressure towards the understanding of the mechanism involved in the nucleation of clay minerals lies in overcoming these energy barriers. As indicated by Caillère and Hénin (1960)<ref name="Caillère-1960">{{Cite journal|vauthors=Caillère S, Hénin S|date=1960|title=Vues d'ensemble sur le problème de la synthèse des minéraux argileux à basse température|journal=Bulletin du Groupe français des argiles|language=fr|volume=12|issue=7|pages=63|doi=10.3406/argil.1960.969}}</ref> the processes involved will have to be studied in well-defined experiments, because it is virtually impossible to isolate the factors involved by mere deduction from complex natural physico-chemical systems such as the ] environment. | |||

| Fripiat and Herbillon (1971),<ref>{{Cite book|title=Soils and tropical weathering: proceedings of the Bandung Symposium 16 to 23 November 1969|vauthors=Fripiat JJ, Herbillon AJ|publisher=]|year=1971|series=Natural resources research|volume=11|location=Paris|pages=15–24|chapter=Formation and transformations of clay minerals in tropical soils|oclc=421565}}</ref> in a review on the formation of kaolinite, raised the fundamental question how a ] material (i.e., the ] fraction of tropical soils) could ever be transformed into a corresponding ordered structure. This transformation seems to take place in soils without major changes in the environment, in a relatively short period of time, and at ambient ] (and ]). | |||

| Low-temperature synthesis of clay minerals (with kaolinite as an example) has several aspects. In the first place the silicic acid to be supplied to the growing crystal must be in a monomeric form, i.e., silica should be present in very dilute solution (Caillère et al., 1957;<ref>{{Cite journal|vauthors=Caillère S, Hénin S, Esquevin J|date=1957|title=Synthèse des minéraux argileux.|journal=Bulletin du Groupe français des argiles|language=fr|volume=9|issue=4|pages=67–76|doi=10.3406/argil.1957.940}}</ref> Caillère and Hénin, 1960;<ref name="Caillère-1960" /> Wey and Siffert, 1962;<ref>{{Cite journal|vauthors=Wey R, Siffert B|date=1961|title=Réactions de la silice monomoléculaire en solutions avec les ions Al3+ et Mg2+|journal=Colloques Internationaux|language=fr|publisher=Centre National des Recherches Scientifiques|volume=105|pages=11–23}}</ref> Millot, 1970<ref>{{Cite book|title=Geology of Clays|last=Millot|first=Georges|publisher=Springer-Verlag|year=1970|isbn=9783662416099|location=New York|translator-last=Paquet|translator-first=H.|doi=10.1007/978-3-662-41609-9|s2cid=128831318 |name-list-style=vanc|translator-last2=Farrand|translator-first2=W. R.}}</ref>). In order to prevent the formation of ] ] ]s precipitating from supersaturated solutions without reacting with the ] or ] ]s to form crystalline ]s, the ] must be present in concentrations below the maximum solubility of amorphous silica. The principle behind this prerequisite can be found in structural chemistry: "Since the polysilicate ions are not of uniform size, they cannot arrange themselves along with the metal ions into a regular crystal lattice." (Iler, 1955, p. 182<ref>{{Cite book|title=The colloid chemistry of silica and silicates|last=Iler|first=R. K.|publisher=Cornell University Press|year=1955|location=Ithaca, N.Y.|name-list-style=vanc}}</ref>) | |||

| The second aspect of the low-temperature synthesis of kaolinite is that the ] cations must be hexacoordinated with respect to ] (Caillère and Hénin, 1947;<ref>{{Cite journal|vauthors=Caillère S, Hénin S|date=1947|title=Formation d'une phyllite du type kaolinique par traitement d'une montmorillonite|journal=Comptes Rendus de l'Académie des Sciences de Paris|volume=224|issue=1|pages=53–55}}</ref> Caillère et al., 1953;<ref>{{Cite journal|vauthors=Caillère S, Hénin S, Esquevin J|date=1953|title=Recherches sur la synthèse des minéraux argileux|journal=Bulletin de la Société française de Minéralogie et de Cristallographie|language=fr|volume=76|issue=7|pages=300–314|doi=10.3406/bulmi.1953.4841}}</ref> Hénin and Robichet, 1955<ref>{{Cite journal|vauthors=Hénin S, Robichet O|date=1955|title=Résultats obtenus au cours de nouveaux essais de synthèse de minéraux argileux|journal=Bulletin du Groupe français des argiles|language=fr|volume=6|issue=1|pages=19–22|doi=10.3406/argil.1955.1257}}</ref>). Gastuche et al. (1962)<ref>{{Cite journal|vauthors=Gastuche MC, Fripiat JJ, DeKimpe C|date=1962|title=La genèse des minéraux argileux de la famille du kaolin. I. – Aspect colloidal|journal=Colloque C.N.R.S.|volume=105|pages=57–65}}</ref> and Caillère and Hénin (1962) have concluded that kaolinite can only ever be formed when the aluminium hydroxide is in the form of ]. Otherwise, the precipitate formed will be a "mixed alumino-silicic gel" (as Millot, 1970, p. 343 put it). If it were the only requirement, large amounts of kaolinite could be harvested simply by adding gibbsite powder to a silica solution. Undoubtedly a marked degree of adsorption of the silica in solution by the gibbsite surfaces will take place, but, as stated before, mere adsorption does not create the layer lattice typical of kaolinite crystals. | |||

| The third aspect is that these two initial components must be incorporated into one mixed crystal with a layer structure. From the following equation (as given by Gastuche and DeKimpe, 1962)<ref>{{Cite journal|vauthors=Gastuche MC, DeKimpe C|date=1962|title=La genèse des minéraux argileux de la famille du kaolin. II. Aspect cristallin|journal=Colloque C.N.R.S.|volume=105|pages=75–88}}</ref> for kaolinite formation | |||

| :<chem>2Al(OH)3 + 2H4SiO4 -> Si2O5 . Al2(OH)4 + 5H2O</chem> | |||

| it can be seen that five molecules of water must be removed from the reaction for every ] of kaolinite formed. Field evidence illustrating the importance of the removal of water from the kaolinite reaction has been supplied by Gastuche and DeKimpe (1962). While studying ] on a ]ic rock in ] (]), they noted how the occurrence of kaolinite depended on the {{lang|fr|"degrée de drainage"}} of the area involved. A clear distinction was found between areas with good ] (i.e., areas with a marked difference between wet and dry seasons) and those areas with poor ] (i.e., ]ly ]y areas). Kaolinite was only found in the areas with distinct seasonal alternations between wet and dry. The possible significance of alternating wet and dry conditions on the transition of ] into kaolinite has been stressed by Tamura and Jackson (1953).<ref>{{Cite journal|last=Tamura T, Jackson ML|date=1953|title=Structural and Energy Relationships in the Formation of Iron and Aluminum Oxides, Hydroxides, and Silicates|journal=]|volume=117|issue=3041|pages=381–383|doi=10.1126/science.117.3041.381|pmid=17749950|bibcode=1953Sci...117..381T}}</ref> The role of alternations between wetting and drying on the formation of kaolinite has also been noted by Moore (1964).<ref>{{Cite journal|vauthors=Moore LR|date=1964|title=The in Situ Formation and Development of Some Kaolinite Macrocrystals|url=https://www.cambridge.org/core/journals/clay-minerals-bulletin/article/in-situ-formation-and-development-of-some-kaolinite-macrocrystals/3B15F40C24CBDF3AF6128FC3C0963C2D|journal=]|volume=5|issue=31|pages=338–352|doi=10.1180/claymin.1964.005.31.02|bibcode=1964ClMin...5..338M}}</ref> | |||

| ===Laboratory syntheses=== | |||

| Syntheses of kaolinite at high temperatures (more than {{convert|100|C|disp=sqbr}}) are relatively well known. There are for example the syntheses of Van Nieuwenberg and Pieters (1929);<ref>{{Cite journal|vauthors=van Nieuwenburg CJ, Pieters HA|date=1929|title=Studies on hydrated aluminium silicates: I. The rehydration of metakaolin and the synthesis of kaolin|journal=]|volume=48|issue=1|pages=27–36|doi=10.1002/recl.19290480106}}</ref> Noll (1934);<ref>{{Cite journal|vauthors=Noll W|date=1934|title=Hydrothermale Synthese des Kaolins|journal=Zeitschrift für Kristallographie, Mineralogie und Petrographie|language=de|volume=45|issue=2–3|pages=175–190|doi=10.1007/BF02943371|bibcode=1934ZKMP...45..175N|s2cid=96869398}}</ref> Noll (1936);<ref>{{Cite journal|vauthors=Noll W|date=1936|title=Über die Bildungsbedingungen von Kaolin, Montmorillonit, Sericit, Pyrophyllit und Analcim|journal=Zeitschrift für Kristallographie, Mineralogie und Petrographie|language=de|volume=48|issue=3–4|pages=210–247|doi=10.1007/BF02939458|bibcode=1936ZKMP...48..210N|s2cid=128744123}}</ref> Norton (1939);<ref>{{Cite journal|vauthors=Norton FH|date=1939|title=Hydrothermal formation of clay minerals in the laboratory|url=https://pubs.geoscienceworld.org/msa/ammin/article-abstract/24/1/1/537069/hydrothermal-formation-of-clay-minerals-in-the|journal=]|volume=24|issue=1|pages=1–17}}</ref> Roy and Osborn (1954);<ref>{{Cite journal|vauthors=Roy R, Osborn EF|date=1954|title=The system Al<sub>2</sub>O<sub>3</sub>-SiO<sub>2</sub>-H<sub>2</sub>O |url=https://pubs.geoscienceworld.org/msa/ammin/article-abstract/39/11-12/853/539421/the-system-al2o3-sio2-h2o|journal=]|volume=39|issue=11–12|pages=853–885}}</ref> Roy (1961);<ref>{{Cite journal|vauthors=Roy R|date=1962|title=The preparation and properties of synthetic clay minerals|journal=Colloque C.N.R.S.|volume=105|pages=83–98}}</ref> Hawkins and Roy (1962);<ref>{{Cite journal|vauthors=Hawkins DB, Roy R|date=1962|title=Electrolytic Synthesis of Kaolinite Under Hydrothermal Conditions|journal=]|volume=45|issue=10|pages=507–508|doi=10.1111/j.1151-2916.1962.tb11044.x}}</ref> Tomura et al. (1985);<ref>{{Cite journal|display-authors=3|vauthors=Tomura S, Shibasaki Y, Mizuta H, Kitamura M|date=1985|title=Growth Conditions and Genesis of Spherical and Platy Kaolinite|journal=Clays and Clay Minerals|volume=33|issue=3|pages=200–206|doi=10.1346/CCMN.1985.0330305|bibcode=1985CCM....33..200T|doi-access=free}}</ref> Satokawa et al. (1994)<ref>{{Cite journal|display-authors=3|vauthors=Satokawa S, Osaki Y, Samejima S, Miyawaki R, Tomura S, Shibasaki Y, Sugahara Y|date=1994|title=Effects of the Structure of Silica-Alumina Gel on the Hydrothermal Synthesis of Kaolinite|journal=Clays and Clay Minerals|volume=42|issue=3|pages=288–297|doi=10.1346/CCMN.1994.0420307|bibcode=1994CCM....42..288S|doi-access=free}}</ref> and Huertas et al. (1999).<ref>{{Cite journal|display-authors=3|vauthors=Huertas FJ, Fiore S, Huertas F, Linares J|date=1999|title=Experimental study of the hydrothermal formation of kaolinite|journal=Chemical Geology|volume=156|issue=1–4|pages=171–190|doi=10.1016/S0009-2541(98)00180-6|bibcode=1999ChGeo.156..171H}}</ref> | |||

| Relatively few low-temperature syntheses have become known (cf. Brindley and DeKimpe (1961);<ref>{{Cite journal|vauthors=Brindley GW, De Kimpe C|date=1961|title=Attempted Low-Temperature Syntheses of Kaolin Minerals|journal=]|volume=190|issue=4772|pages=254|doi=10.1038/190254a0|bibcode=1961Natur.190..254B|s2cid=4149442|doi-access=free}}</ref> DeKimpe (1969);<ref>{{Cite journal|vauthors=De Kimpe CR|date=1969|title=Crystallization of kaolinite at low temperature from an alumino-silicic gel|journal=Clays and Clay Minerals|volume=17|issue=1|pages=37–38|doi=10.1346/CCMN.1969.0170107|bibcode=1969CCM....17...37D|doi-access=free}}</ref> Bogatyrev et al. (1997)<ref>{{Cite journal|display-authors=3|vauthors=Bogatyrev BA, Mateeva LA, Zhukov VV, Magazina LO|date=1997|title=Low-temperature synthesis of kaolinite and halloysite on the gibbsite – silicic acid solution system|journal=Transactions (Doklady) of the Russian Academy of Sciences|series=Earth science sections|volume=353 A|pages=403–405}}</ref>). | |||

| Laboratory syntheses of kaolinite at room temperature and atmospheric pressure have been described by DeKimpe et al. (1961).<ref>{{Cite journal|vauthors=DeKimpe CR, Gastuche MC, Brindley GW|date=1961|title=Ionic coordination in alumino-silicic acids in relation to clay mineral formation|url=http://rruff.info/doclib/am/vol46/AM46_1370.pdf|journal=]|volume=46|issue=11–12|pages=1370–1381}}</ref> From those tests the role of periodicity becomes convincingly clear. DeKimpe et al. (1961) had used daily additions of ] (as {{Chem2|AlCl3*6 H2O}}) and ] (in the form of ]) during at least two months. In addition, adjustments of the pH took place every day by way of adding either ] or ]. Such daily additions of Si and Al to the solution in combination with the daily titrations with ] or ] during at least 60 days will have introduced the necessary element of periodicity. Only now the actual role of what has been described as the "aging" (''Alterung'') of amorphous alumino-silicates (as for example Harder, 1978<ref>{{Cite journal|vauthors=Harder H|date=1978|title=Synthesen von Tonmineralen unter spezieller Berücksichtigung festländischer Bedingungen|journal=Schriftenreihe für geologische Wissenschaften (Berlin)|language=de|volume=11|pages=51–78}}</ref> had noted) can be fully understood. As such, time is not bringing about any change in a closed system at equilibrium; but a series of alternations of periodically changing conditions (by definition, taking place in an open system) will bring about the low-temperature formation of more and more of the stable phase kaolinite instead of (ill-defined) amorphous alumino-silicates. | |||

| ==Applications== | |||

| ===Main=== | |||

| In 2009, up to 70% of kaolin was used in the production of ]. Following reduced demand from the paper industry, resulting from both competing minerals and the effect of digital media, in 2016 the market share was reported to be: paper, 36%; ceramics, 31%; paint, 7% and other, 26%.<ref name="Ceramics' F. Hart 2019. Pg.28">'Positive Outlook For Kaolin In Ceramics' F. Hart, I. Wilson. Industrial Minerals, April 2019. Pg.28</ref><ref>{{cite journal |last1=King |first1=R.J. |title=Kaolinite |journal=Geology Today |date=March 2009 |volume=25 |issue=2 |pages=75–78 |doi=10.1111/j.1365-2451.2009.00711.x|bibcode=2009GeolT..25...75K |s2cid=242917623 }}</ref> According to the ], in 2021 the global production of kaolin was estimated to be around 45 million tonnes.<ref>U.S. Geological Survey, Mineral Commodity Summaries, January 2022</ref> | |||

| * '''Paper''' applications require high-brightness, low abrasion and delaminated kaolins. For paper coatings it is used to enhance the gloss, brilliance, smoothness and receptability to inks; it can account for 25% of mass of the paper. As a paper filler it is used as a pulp extender, and to increase opacity; it can account for 15% of mass.<ref>’Industrial Minerals And Their Uses - A Handbook And Formulary. P. A. Ciullo. William Andrew, 1996. Pg. 43</ref><ref name="Markets And Industry Outlook 2013. Pg. 332">'Kaolin - Global Markets And Industry Outlook' 13th edition. Roskill Information Services, 2013. Pg. 332</ref><ref>{{Cite journal|vauthors=Murray HH, Lyons SC|date=1955|title=Correlation of Paper-Coating Quality with Degree of Crystal Perfection of Kaolinite|journal=Clays and Clay Minerals|volume=4|issue=1|pages=31–40|doi=10.1346/CCMN.1955.0040105|bibcode=1955CCM.....4...31M|doi-access=free}}</ref> | |||

| * In whiteware '''ceramic''' bodies, kaolin can constitute up to 50% of the raw materials. In unfired bodies it contributes to the green strength, plasticity and rheological properties, such as the casting rate. During firing it reacts with other body components to form the crystal and glass phases. With suitable firing schedules it is key to the formation of ]. The most valued grades have low contents of chromophoric oxides such that the fired material has high whiteness.<ref>’Industrial Minerals And Their Uses - A Handbook And Formular’ P. A. Ciullo. William Andrew, 1996. Pg. 43</ref><ref name="Markets And Industry Outlook 2013. Pg. 332"/><ref>’Dictionary Of Ceramic Science And Engineering' L. S. O’Bannon. Plenum Press / Springer. 1984. Pg.146</ref><ref>’Dictionary Of Ceramic Science And Engineering’ 3rd edition. I. MCcolm. Springer, 2013</ref> In glazes it is primarily used as a rheology control agent, but also contributes some green strength. In both glazes and frits it contributes some SiO<sub>2</sub> as a glass network former, and Al<sub>2</sub>O<sub>3</sub> as both a network former and modifier.<ref>'Ceramics Glaze Technology.' J.R.Taylor & A.C.Bull. The Institute Of Ceramics/Pergamon Press986</ref> | |||

| ===Other industrial=== | |||

| * As a raw material for the production of an insulation material called Kaowool (a form of ]). | |||

| * An additive to some ]s to extend the ] ({{Chem2|TiO2}}) white pigment and modify gloss levels. | |||

| * An additive to modify the properties of ] upon ]. | |||

| * An additive to adhesives to modify ].<ref>{{cite book|url=https://books.google.com/books?id=qQPozu9fWrIC&pg=PA43|title=Industrial Minerals and Their Uses: A Handbook and Formulary|last=Ciullo|first=Peter A.|publisher=Noyes Publications|year=1996|isbn=9780815518082|location=Westwood, NJ|pages=41–43|name-list-style=vanc}}</ref> | |||

| * As adsorbents in water and wastewater treatment.<ref>{{cite journal|display-authors=3|vauthors=Leiviskä T, Gehör S, Eijärvi E, Sarpola A, Tanskanen J|date=2012|title=Characteristics and potential applications of coarse clay fractions from Puolanka, Finland|journal=]|volume=2|issue=2|pages=239–247|bibcode=2012CEJE....2..239L|doi=10.2478/s13531-011-0067-9|doi-access=free}}</ref> | |||

| * In its altered ] form, as a ]; when added to a concrete mix, metakaolin accelerates the hydration of ] and takes part in the ] with the ] formed in the hydration of the main cement minerals (e.g. ]). | |||

| * ] is also a base component for ] compounds. | |||

| ===Medical=== | |||

| * To soothe an upset ], similar to the way ]s (and later, humans) in ] originally used it<ref>{{Cite journal|vauthors=Diamond JM|date=1999|title=Dirty eating for healthy living|journal=]|series=Evolutionary biology|volume=400|issue=6740|pages=120–121|bibcode=1999Natur.400..120D|doi=10.1038/22014|pmid=10408435|doi-access=free}}</ref> (more recently, industrially produced). | |||

| * Kaolin-based preparations are used for treatment of ]. | |||

| * An ingredient in 'pre-work' skin protection and ]s.<ref>{{cite web|url=https://www.debgroup.com/sites/default/files/uploads/product-sheets/en-us/stokoderm_protect_pure_pi.pdf|title=Stokoderm Protect PURE|date=2017|website=debgroup.com|publisher=Deb USA, Inc.|type=product leaflet|access-date=12 April 2018}}</ref> | |||

| * To induce and accelerate blood clotting. In April 2008 the US ] announced the successful use of a kaolinite-derived ] infusion in traditional ].<ref>{{cite news|url=https://www.wired.com/medtech/health/news/2008/04/blood_clotting|title=Nanoparticles Help Gauze Stop Gushing Wounds|last=Rowe A|date=24 April 2008|magazine=Wired|access-date=5 August 2009|archive-url=https://web.archive.org/web/20090706091649/http://www.wired.com/medtech/health/news/2008/04/blood_clotting|archive-date=6 July 2009|url-status=live|publisher=Condé Nast}}</ref> which is still the hemostat of choice for all branches of the US military. See ] and ] | |||

| * As a mild abrasive in ]. | |||

| ===Cosmetics=== | |||

| * As a filler in ]. | |||

| * For facial masks or soap. | |||

| * for spa body treatments, such as body wraps, cocoons, or spot treatments. | |||

| ===Archaeology=== | |||

| * As an indicator in ] since kaolinite can contain very small traces of ] and ]. | |||

| ===Geophagy=== | |||

| * Humans sometimes eat kaolin for pleasure or to suppress hunger,<ref name="Balengou">{{Cite news|url=http://www.quotidienlejour.com/double-page-/reportage/504-balengou-autour-des-mines|title=Balengou: autour des mines|last=Kamtche F|date=2012|work=Le Jour|access-date=22 March 2019|archive-url=https://web.archive.org/web/20120304025224/http://www.quotidienlejour.com/double-page-/reportage/504-balengou-autour-des-mines|archive-date=4 March 2012|url-status=dead|language=fr|trans-title=Balengou: around the mines}}</ref> a practice known as ]. In Africa, kaolin used for such purposes is known as ''kalaba'' (in ]<ref>Karine Boucher, Suzanne Lafage. ''Le Français en Afrique: Revue du Réseau des Observatoires du Français Contemporain en Afrique''. 2000.</ref> and ]<ref name="Balengou"/>), ''calaba'', and ''calabachop'' (in ]). Consumption is greater among women, especially during pregnancy,<ref>Gerald N. Callahan. '']''. 9.8 (August 2003).</ref> and its use is sometimes said by women of the region to be a habit analogous to cigarette smoking among men. The practice has also been observed within a small population of African-American women in the ], especially ], likely brought with the traditions of the aforementioned Africans via ].<ref name="Clay Eating">{{Cite encyclopedia|title=Clay Eating|date=3 February 2004|encyclopedia=]|last=Grigsby RK|series=Science & Medicine|type=online|url=https://www.georgiaencyclopedia.org/articles/science-medicine/clay-eating|access-date=2019-10-20}}</ref><ref>{{Cite news|url=https://www.npr.org/sections/thesalt/2014/04/02/297881388/the-old-and-mysterious-practice-of-eating-dirt-revealed?t=1553254886529|title=The Old And Mysterious Practice of Eating Dirt, Revealed|last=Chen L|date=2 April 2014|work=The Salt|publisher=NPR}}</ref> There, the kaolin is called ''white dirt'', ''chalk'' or ''white clay''.<ref name="Clay Eating"/> | |||

| ===Geotechnical engineering=== | |||

| * Research results show that the utilization of kaolinite in ] can be alternatively replaced by safer illite, especially if its presence is less than 10.8% of the total rock mass.<ref>{{cite journal |last1=Supandi |first1=Supandi |last2=Zakaria |first2=Zufialdi |last3=Sukiyah |first3=Emi |last4=Sudradjat |first4=Adjat |title=The Influence of Kaolinite - Illite toward mechanical properties of Claystone |journal=Open Geosciences |date=2019-08-29 |volume=11 |issue=1 |pages=440–446 |doi=10.1515/geo-2019-0035|bibcode=2019OGeo...11...35S |doi-access=free }}</ref> | |||

| ===Small-scale uses=== | |||

| * As a light-diffusing material in white ]s. | |||

| * In ] as a ] applied to crops to deter ] damage, and in the case of apples, to prevent sun scald. | |||

| * As ] in traditional stone masonry homes in Nepal. | |||

| * As a filler in ].<ref>{{Cite web|url=http://www.gracyk.com/diamonddisc.shtml|title=Edison Diamond Discs: 1912 - 1929|last=Gracyk T|date=2006|website=Tim Gracyk's Phonographs, Singers, & Old Records|access-date=22 March 2019}}</ref> | |||

| ==Production output== | |||

| Global production of kaolin by country in 2012 was estimated to be:<ref>'Kaolin - Global Markets And Industry Outlook' 13th edition. Roskill Information Services, 2013. Pgs. 28-30</ref> | |||

| {| class="wikitable collapsible" | |||

| |+'000 tonnes | |||

| ! Global - total !! 26,651 | |||

| |- | |||

| ! | |||

| | | |||

| |- | |||

| ! Egypt | |||

| | 275 | |||

| |- | |||

| ! Nigeria | |||

| | 100 | |||

| |- | |||

| ! Algeria | |||

| | 80 | |||

| |- | |||

| ! Tanzania | |||

| | 45 | |||

| |- | |||

| ! Sudan | |||

| | 35 | |||

| |- | |||

| ! Uganda | |||

| | 30 | |||

| |- | |||

| ! South Africa | |||

| | 15 | |||

| |- | |||

| ! Ethiopia | |||

| | 2 | |||

| |- | |||

| ! Kenya | |||

| | 1 | |||

| |- | |||

| ! Africa - total | |||

| | 583 | |||

| |- | |||

| ! | |||

| | | |||

| |- | |||

| ! China | |||

| | 3,950 | |||

| |- | |||

| ! South Korea | |||

| | 800 | |||

| |- | |||

| ! Vietnam | |||

| | 650 | |||

| |- | |||

| ! Malaysia | |||

| | 450 | |||

| |- | |||

| ! Thailand | |||

| | 180 | |||

| |- | |||

| ! Indonesia' | |||

| | 175 | |||

| |- | |||

| ! India | |||

| | 75 | |||

| |- | |||

| ! Bangladesh | |||

| | 20 | |||

| |- | |||

| ! Taiwan | |||

| | 17 | |||

| |- | |||

| ! Pakistan | |||

| | 15 | |||

| |- | |||

| ! Sri Lanka | |||

| | 11 | |||

| |- | |||

| ! Japan | |||

| | 3 | |||

| |- | |||

| ! Philippines | |||

| | 2 | |||

| |- | |||

| ! Asia - total | |||

| | 6,348 | |||

| |- | |||

| ! | |||

| | | |||

| |- | |||

| ! Germany | |||

| | 4,800 | |||

| |- | |||

| ! UK | |||

| | 1,000 | |||

| |- | |||

| ! Czech Republic | |||

| | 650 | |||

| |- | |||

| ! Italy | |||

| | 625 | |||

| |- | |||

| ! France | |||

| | 350 | |||

| |- | |||

| ! Portugal | |||

| | 325 | |||

| |- | |||

| ! Spain | |||

| | 300 | |||

| |- | |||

| ! ] | |||

| | 250 | |||

| |- | |||

| ! Bulgaria | |||

| | 225 | |||

| |- | |||

| ! Russia | |||

| | 170 | |||

| |- | |||

| ! Poland | |||

| | 125 | |||

| |- | |||

| ! Ukraine | |||

| | 100 | |||

| |- | |||

| ! Serbia | |||

| | 90 | |||

| |- | |||

| ! Austria | |||

| | 65 | |||

| |- | |||

| ! Denmark | |||

| | 3 | |||

| |- | |||

| ! Europe - total | |||

| | 9,078 | |||

| |- | |||

| ! | |||

| | | |||

| |- | |||

| ! USA | |||

| | 5,900 | |||

| |- | |||

| ! Mexico | |||

| | 120 | |||

| |- | |||

| ! N. America - total | |||

| | 6,020 | |||

| |- | |||

| ! | |||

| | | |||

| |- | |||

| ! Iran | |||

| | 1,500 | |||

| |- | |||

| ! Turkey | |||

| | 725 | |||

| |- | |||

| ! Jordan | |||

| | 100 | |||

| |- | |||

| ! Saudi Arabia | |||

| | 70 | |||

| |- | |||

| ! Iraq | |||

| | 3 | |||

| |- | |||

| ! Middle East - total | |||

| | 2,398 | |||

| |- | |||

| ! | |||

| | | |||

| |- | |||

| ! Australia | |||

| | 40 | |||

| |- | |||

| ! New Zealand | |||

| | 11 | |||

| |- | |||

| ! Oceania - total | |||

| | 51 | |||

| |- | |||

| ! | |||

| | | |||

| |- | |||

| ! Brazil | |||

| | 1,900 | |||

| |- | |||

| ! Argentina | |||

| | 80 | |||

| |- | |||

| ! Paraguay | |||

| | 66 | |||

| |- | |||

| ! Chile | |||

| | 60 | |||

| |- | |||

| ! Colombia | |||

| | 20 | |||

| |- | |||

| ! Peru | |||

| | 20 | |||

| |- | |||

| ! Ecuador | |||

| | 15 | |||

| |- | |||

| ! Venezuela | |||

| | 10 | |||

| |- | |||

| ! Guatemala | |||

| | 2 | |||

| |- | |||

| ! S. & C. America - total | |||

| | 2,173 | |||

| |} | |||

| ==Typical properties== | |||

| Some selected typical properties of various ceramic grade kaolins are:<ref name="Ceramics' F. Hart 2019. Pg.28"/> | |||

| {| class="wikitable collapsible" | |||

| ! Product name !! SSP !! Premium !! Longyan 325# !! Zettlitz 1A !! OKA | |||

| |- | |||

| ! Country | |||

| | UK || New Zealand || China || Czech Republic || Germany | |||

| |- | |||

| ! Manufacturer | |||

| | Imerys || Imerys || Logyan || Sedlecky || AKW | |||

| |- | |||

| ! | |||

| | || || || || | |||

| |- | |||

| ! % < 2 μm | |||

| | 85 || 97 || 25 || 56 || 82 | |||

| |- | |||

| ! % <1 μm | |||

| | 50 || 88 || 15 || 41 || 50 | |||

| |- | |||

| ! | |||

| | || || || || | |||

| |- | |||

| ! SiO<sub>2</sub>, % | |||

| | 48.0 || 49.5 || 49.3 || 48.0 || 49.5 | |||

| |- | |||

| ! Al<sub>2</sub>O<sub>3</sub>, % | |||

| | 37.0 || 35.5 || 35.5 || 37.0 || 35.5 | |||

| |- | |||

| ! Fe<sub>2</sub>O<sub>3</sub>, % | |||

| | 0.44 || 0.29 || 0.22 || 0.68 || 0.43 | |||

| |- | |||

| ! TiO<sub>2</sub>, % | |||

| | 0.01 || 0.09 || 0.01 || 0.20 || 0.17 | |||

| |- | |||

| ! CaO, % | |||

| | 0.10 || -|| 0.03 || 0.08 || 0.20 | |||

| |- | |||

| ! MgO, % | |||

| | 0.25 || -|| 0.25 || 0.23 || 0.02 | |||

| |- | |||

| ! K<sub>2</sub>O, % | |||

| | 1.25 || -|| 1.90 || 0.92 || 0.30 | |||

| |- | |||

| ! Na<sub>2</sub>O, % | |||

| | 0.15 || -|| 0.09 || 0.07 || 0.01 | |||

| |- | |||

| ! LOI, % | |||

| | 12.8 || 13.8 || 11.9 || 12.9 || 13.4 | |||

| |- | |||

| ! | |||

| | || || || || | |||

| |- | |||

| ! Kaolinite, % | |||

| | 95 || -|| 40 || 89 || 86 | |||

| |- | |||

| ! Halloysite, % | |||

| | -|| 92 || 40 || -|| - | |||

| |- | |||

| ! Mica, % | |||

| | 4 || -|| -|| -|| - | |||

| |- | |||

| ! Quartz, % | |||

| | 1 || 4 || 3 || 1 || 8 | |||

| |- | |||

| ! Smectite, % | |||

| | -|| -|| -|| 1 || 6 | |||

| |- | |||

| ! Cristobalite, % | |||

| | -|| 4 || -|| -|| - | |||

| |} | |||

| ==Safety== | |||

| {{NFPA 704 | H= 1 | F= 0 | R= 0 | S= |caption=Kaolin |ref=<ref name=MSDS>{{cite web |title=Material Safety Data Sheet: Kaolin |url=https://www.conncoll.edu/media/website-media/offices/ehs/envhealthdocs/Tile-6_Kaolin.pdf |website=Connecticut College |publisher=Imerys Pigments and Additives Group |access-date=11 November 2021}}</ref>}} | |||

| Kaolin is ], but may cause mild irritation of the skin or mucous membranes. Kaolin products may also contain traces of ], a known ] if inhaled.<ref name=MSDS/> | |||

| In the US, the ] (OSHA) has set the legal limit (]) for kaolin exposure in the workplace as 15 mg/m<sup>3</sup> total exposure and 5 mg/m<sup>3</sup> respiratory exposure over an 8-hour workday. The ] (NIOSH) has set a ] (REL) of 10 mg/m<sup>3</sup> total exposure TWA 5 mg/m<sup>3</sup> respiratory exposure over an 8-hour workday.<ref>{{Cite web|url=https://www.cdc.gov/niosh/npg/npgd0364.html|title=Kaolin|website=] Pocket Guide to Chemical Hazards|publisher=]|access-date=6 November 2015}}</ref> | |||

| ==See also== | ==See also== | ||

| {{colbegin}} | |||

| ] | |||

| * {{annotated link|China stone}} | |||

| * ] | |||

| * {{annotated link|Clay pit}} | |||

| * ] | |||

| * {{annotated link|Dickite}} | |||

| * ] | |||

| * {{annotated link|Halloysite}} | |||

| * ] | |||

| * {{annotated link|Kaolin Deposits of Charentes Basin, France}} | |||

| * ] | |||

| * {{annotated link|Kaolin spray}} | |||

| * ] | |||

| * {{annotated link|Medicinal clay}} | |||

| * ] | |||

| * {{annotated link|Nacrite}} | |||

| * ] | |||

| * {{annotated link|Cornish China Clay Branches}} | |||

| * ] | |||

| {{colend}} | |||

| ==References== | ==References== | ||

| ===Bibliography=== | |||

| * Deer, W.A., Howie, R.A., and Zussman, J. (1992) ''An introduction to the rock-forming minerals (2nd ed.)''. Harlow: Longman ISBN 0-582-30094-0. | |||

| * Hurlbut, Cornelius S., Klein, Cornelis (1985) ''Manual of Mineralogy - after J. D. Dana'', 20th ed., Wiley, pp. 428 - 429, ISBN 0-471-80580-7. | |||

| * Breck, D.W. (1984)''Zeolite Molecular Sieves'', Robert E. Brieger Publishing Company: Malabar, FL, pp. 314–315, ISBN 0-89874-648-5. | |||

| * Bellotto, M., Gualtieri, A., Artioli, G., and Clark, S.M. (1995) ''Kinetic study of the kaolinite-mullite reaction sequence. Part I: kaolinite dehydroxylation', Phys. Chem. Minerals, Vol 22, 207-214. | |||

| * | |||

| * | |||

| === |

===Citations=== | ||

| {{ |

{{Reflist}} | ||

| ===General references=== | |||

| {{refbegin}} | |||

| * {{Cite book |title=Zeolite Molecular Sieves |last=Breck |first=D. W. |publisher=R.E. Krieger Publishing Co. |year=1984 |isbn=0898746485 |location=] |pages=314–315 }} | |||

| * {{Cite book |title=An Introduction to the Rock-Forming Minerals |last1=Deer |first1=W. A. |last2=Howie|first2=R.A. |last3=Zussman|first3=J. |publisher=Longman |year=1992 |isbn=0582300940 |edition=2nd |location=Harlow |title-link=An Introduction to the Rock-Forming Minerals }} | |||

| * {{Cite book|title=Manual of Mineralogy... |author3=J.D. Dana |last=Hurlbut |first=C. S. |author2=C. Klein |display-authors=1 |ref={{harvid|Hurlbut & al.|1985}} |publisher=Wiley |year=1985 |isbn=0471805807 |edition=20th |pages= |url-access=registration |url=https://archive.org/details/manualofmineralo00klei/page/428 }} | |||

| * {{citation |last=Needham |first=Joseph |author2=Rose Kerr |author3=Nigel Wood |author4=Ts'ai Mei-fen |author5=Zhang Fukang |display-authors=1 |ref={{harvid|Needham & al.|2004}} |date=2004 |author-link=Joseph Needham |url=https://books.google.com/books?id=mabcHwmAD5oC |title=Science and Civilisation in China, ''Vol. 5:'' Chemistry and Chemical Technology, ''Part XII:'' Ceramic Technology |editor=Rose Kerr |editor2=Christopher Cullen |display-editors=0 |location=] |publisher=Cambridge University Press |isbn=0-521-83833-9 |contribution=Chinese Porcelain and the City of Ching-te-chen |contribution-url=https://books.google.com/books?id=mabcHwmAD5oC&pg=PA184 |pages= }}. | |||

| * {{cite journal |url=http://www.elementsmagazine.org/toc/toc_v10n3.pdf |access-date=14 September 2022 |title=Kaolin |date = June 2014 | volume=10 | number=3 |editor-last1=Schroeder |editor-first1=Paul A. |editor-last2=Erickson |editor-first2=Gary |display-editors=1 |ref={{harvid|Schroeder & al.|2022}} |journal=Elements}} | |||

| {{refend}} | |||

| ==External links== | ==External links== | ||

| * | |||

| * | |||

| {{Phyllosilicates}} | |||

| {{Clay minerals}} | |||

| {{Authority control}} | |||

| ] | |||

| ] | ] | ||

| ] | ] | ||

| ] | ] | ||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

Latest revision as of 15:46, 19 January 2025

Phyllosilicate clay mineral "Kaolin" redirects here. For other uses, see Kaolin (disambiguation). See also: Aluminium silicate

| Kaolinite | |

|---|---|

| |

| General | |

| Category | Phyllosilicates Kaolinite-serpentine group |

| Formula (repeating unit) | Al2Si2O5(OH)4, or in oxide notation: Al2O3·2SiO2·2H2O |

| IMA symbol | Kln |

| Strunz classification | 9.ED.05 |

| Crystal system | Triclinic |

| Crystal class | Pedial (1) (same H-M symbol) |

| Space group | P1 |

| Unit cell | a = 5.13 Å, b = 8.89 Å c = 7.25 Å; α = 90° β = 104.5°, γ = 89.8°; Z = 2 |

| Identification | |

| Color | White to cream, sometimes red, blue or brown tints from impurities and pale-yellow; also often stained various hues, tans and browns being common. |

| Crystal habit | Rarely as crystals, thin plates or stacked. More commonly as microscopic pseudohexagonal plates and clusters of plates, aggregated into compact, claylike masses. |

| Cleavage | Perfect on {001} |

| Tenacity | Flexible but inelastic |

| Mohs scale hardness | 2–2.5 |

| Luster | Pearly to dull earthy |

| Streak | White |

| Specific gravity | 2.16–2.68 |

| Optical properties | Biaxial (–) |

| Refractive index | nα = 1.553–1.565, nβ = 1.559–1.569, nγ = 1.569–1.570 |

| 2V angle | Measured: 24° to 50°, Calculated: 44° |

| References | |

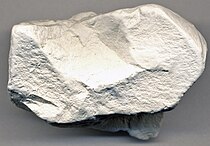

Kaolinite (/ˈkeɪ.ələˌnaɪt, -lɪ-/ KAY-ə-lə-nyte, -lih-; also called kaolin) is a clay mineral, with the chemical composition Al2Si2O5(OH)4. It is a layered silicate mineral, with one tetrahedral sheet of silica (SiO4) linked through oxygen atoms to one octahedral sheet of alumina (AlO6).

Kaolinite is a soft, earthy, usually white, mineral (dioctahedral phyllosilicate clay), produced by the chemical weathering of aluminium silicate minerals like feldspar. It has a low shrink–swell capacity and a low cation-exchange capacity (1–15 meq/100 g).

Rocks that are rich in kaolinite, and halloysite, are known as kaolin (/ˈkeɪ.əlɪn/) or china clay. In many parts of the world kaolin is colored pink-orange-red by iron oxide, giving it a distinct rust hue. Lower concentrations of iron oxide yield the white, yellow, or light orange colors of kaolin. Alternating lighter and darker layers are sometimes found, as at Providence Canyon State Park in Georgia, United States.

Kaolin is an important raw material in many industries and applications. Commercial grades of kaolin are supplied and transported as powder, lumps, semi-dried noodle or slurry. Global production of kaolin in 2021 was estimated to be 45 million tonnes, with a total market value of US $4.24 billion.

Names

The English name kaolin was borrowed in 1727 from François Xavier d'Entrecolles's 1712 French reports on the manufacture of Jingdezhen porcelain. D'Entrecolles was transcribing the Chinese term 高嶺土, now romanized as gāolǐngtǔ in pinyin, taken from the name of the village of Gaoling ("High Ridge") near Ehu in Fuliang County, now part of Jiangxi Province's Jingdezhen Prefecture. The area around the village had become the main source of Jingdezhen's kaolin over the course of the Qing dynasty. The mineralogical suffix -ite was later added to generalize the name to cover nearly identical minerals from other locations.

Kaolinite is also occasionally discussed under the archaic names lithomarge and lithomarga from Latin lithomarga, a combination of litho- (Ancient Greek: λίθος,líthos, "stone") and marga ("marl"). In more proper modern use, lithomarge now refers specifically to a compacted and massive form of kaolin.

Chemistry

Notation

The chemical formula for kaolinite as written in mineralogy is Al2Si2O5(OH)4, however, in ceramics applications the same formula is typically written in terms of oxides, thus giving Al2O3·2SiO2·2H2O.

Structure

Compared with other clay minerals, kaolinite is chemically and structurally simple. It is described as a 1:1 or TO clay mineral because its crystals consist of stacked TO layers. Each TO layer consists of a tetrahedral (T) sheet composed of silicon and oxygen ions bonded to an octahedral (O) sheet composed of oxygen, aluminium, and hydroxyl ions. The T sheet is so called because each silicon ion is surrounded by four oxygen ions forming a tetrahedron. The O sheet is so called because each aluminium ion is surrounded by six oxygen or hydroxyl ions arranged at the corners of an octahedron. The two sheets in each layer are strongly bonded together via shared oxygen ions, while layers are bonded via hydrogen bonding between oxygen on the outer face of the T sheet of one layer and hydroxyl on the outer face of the O sheet of the next layer.

-

View of the structure of the tetrahedral (T) sheet of kaolinite

View of the structure of the tetrahedral (T) sheet of kaolinite

-

View of the structure of the octahedral (O) sheet of kaolinite

View of the structure of the octahedral (O) sheet of kaolinite

-

Kaolinite crystal structure looking along the layers

Kaolinite crystal structure looking along the layers

A kaolinite layer has no net electrical charge and so there are no large cations (such as calcium, sodium, or potassium) between layers as with most other clay minerals. This accounts for kaolinite's relatively low ion exchange capacity. The close hydrogen bonding between layers also hinders water molecules from infiltrating between layers, accounting for kaolinite's nonswelling character.

When moistened, the tiny platelike crystals of kaolinite acquire a layer of water molecules that cause crystals to adhere to each other and give kaolin clay its cohesiveness. The bonds are weak enough to allow the plates to slip past each other when the clay is being molded, but strong enough to hold the plates in place and allow the molded clay to retain its shape. When the clay is dried, most of the water molecules are removed, and the plates hydrogen bond directly to each other, so that the dried clay is rigid but still fragile. If the clay is moistened again, it will once more become plastic.

Structural transformations

Kaolinite group clays undergo a series of phase transformations upon thermal treatment in air at atmospheric pressure.

Milling

High-energy milling of kaolin results in the formation of a mechanochemically amorphized phase similar to metakaolin, although the properties of this solid are quite different. The high-energy milling process is highly inefficient and consumes a large amount of energy.

Drying

See also: Buell dryerBelow 100 °C, exposure to low humidity air will result in the slow evaporation of any liquid water in the kaolin. At low moisture content the mass can be described leather dry, and at near 0% moisture it is referred to as bone dry.

Above 100 °C any remaining free water is lost. Above around 400 °C hydroxyl ions (OH) are lost from the kaolinite crystal structure in the form of water: the material cannot now be plasticised by absorbing water. This is irreversible, as are subsequent transformations; this is referred to as calcination.

Metakaolin

Endothermic dehydration of kaolinite begins at 550–600 °C producing disordered metakaolin, but continuous hydroxyl loss is observed up to 900 °C (1,650 °F). Although historically there was much disagreement concerning the nature of the metakaolin phase, extensive research has led to a general consensus that metakaolin is not a simple mixture of amorphous silica (SiO2) and alumina (Al2O3), but rather a complex amorphous structure that retains some longer-range order (but not strictly crystalline) due to stacking of its hexagonal layers.

Spinel

Further heating to 925–950 °C converts metakaolin to an aluminium-silicon spinel which is sometimes also referred to as a gamma-alumina type structure:

Platelet mullite

Upon calcination above 1050 °C, the spinel phase nucleates and transforms to platelet mullite and highly crystalline cristobalite:

Needle mullite

Finally, at 1400 °C the "needle" form of mullite appears, offering substantial increases in structural strength and heat resistance. This is a structural but not chemical transformation. See stoneware for more information on this form.

Occurrence

Kaolinite is one of the most common minerals; it is mined, as kaolin, in Australia, Brazil, Bulgaria, China, Czech Republic, France, Germany, India, Iran, Malaysia, South Africa, South Korea, Spain, Tanzania, Thailand, United Kingdom, United States and Vietnam.

Mantles of kaolinite are common in Western and Northern Europe. The ages of these mantles are Mesozoic to Early Cenozoic.

Kaolinite clay occurs in abundance in soils that have formed from the chemical weathering of rocks in hot, moist climates; for example in tropical rainforest areas. Comparing soils along a gradient towards progressively cooler or drier climates, the proportion of kaolinite decreases, while the proportion of other clay minerals such as illite (in cooler climates) or smectite (in drier climates) increases. Such climatically related differences in clay mineral content are often used to infer changes in climates in the geological past, where ancient soils have been buried and preserved.

In the Institut National pour l'Étude Agronomique au Congo Belge (INEAC) classification system, soils in which the clay fraction is predominantly kaolinite are called kaolisol (from kaolin and soil).

In the United States, the main kaolin deposits are found in central Georgia, on a stretch of the Atlantic Seaboard fall line between Augusta and Macon. This area of thirteen counties is called the "white gold" belt; Sandersville is known as the "Kaolin Capital of the World" due to its abundance of kaolin. In the late 1800s, an active kaolin surface-mining industry existed in the extreme southeast corner of Pennsylvania, near the towns of Landenberg and Kaolin, and in what is present-day White Clay Creek Preserve. The product was brought by train to Newark, Delaware, on the Newark-Pomeroy line, along which can still be seen many open-pit clay mines. The deposits were formed between the late Cretaceous and early Paleogene, about 100 to 45 million years ago, in sediments derived from weathered igneous and metakaolin rocks. Kaolin production in the United States during 2011 was 5.5 million tons.

During the Paleocene–Eocene Thermal Maximum sediments deposited in the Espluga Freda area of Spain were enriched with kaolinite from a detrital source due to denudation.

Synthesis and genesis

Difficulties are encountered when trying to explain kaolinite formation under atmospheric conditions by extrapolation of thermodynamic data from the more successful high-temperature syntheses. La Iglesia and Van Oosterwijk-Gastuche (1978) thought that the conditions under which kaolinite will nucleate can be deduced from stability diagrams, based as they are on dissolution data. Because of a lack of convincing results in their own experiments, La Iglesia and Van Oosterwijk-Gastuche (1978) had to conclude, however, that there were other, still unknown, factors involved in the low-temperature nucleation of kaolinite. Because of the observed very slow crystallization rates of kaolinite from solution at room temperature Fripiat and Herbillon (1971) postulated the existence of high activation energies in the low-temperature nucleation of kaolinite.

At high temperatures, equilibrium thermodynamic models appear to be satisfactory for the description of kaolinite dissolution and nucleation, because the thermal energy suffices to overcome the energy barriers involved in the nucleation process. The importance of syntheses at ambient temperature and atmospheric pressure towards the understanding of the mechanism involved in the nucleation of clay minerals lies in overcoming these energy barriers. As indicated by Caillère and Hénin (1960) the processes involved will have to be studied in well-defined experiments, because it is virtually impossible to isolate the factors involved by mere deduction from complex natural physico-chemical systems such as the soil environment. Fripiat and Herbillon (1971), in a review on the formation of kaolinite, raised the fundamental question how a disordered material (i.e., the amorphous fraction of tropical soils) could ever be transformed into a corresponding ordered structure. This transformation seems to take place in soils without major changes in the environment, in a relatively short period of time, and at ambient temperature (and pressure).

Low-temperature synthesis of clay minerals (with kaolinite as an example) has several aspects. In the first place the silicic acid to be supplied to the growing crystal must be in a monomeric form, i.e., silica should be present in very dilute solution (Caillère et al., 1957; Caillère and Hénin, 1960; Wey and Siffert, 1962; Millot, 1970). In order to prevent the formation of amorphous silica gels precipitating from supersaturated solutions without reacting with the aluminium or magnesium cations to form crystalline silicates, the silicic acid must be present in concentrations below the maximum solubility of amorphous silica. The principle behind this prerequisite can be found in structural chemistry: "Since the polysilicate ions are not of uniform size, they cannot arrange themselves along with the metal ions into a regular crystal lattice." (Iler, 1955, p. 182)

The second aspect of the low-temperature synthesis of kaolinite is that the aluminium cations must be hexacoordinated with respect to oxygen (Caillère and Hénin, 1947; Caillère et al., 1953; Hénin and Robichet, 1955). Gastuche et al. (1962) and Caillère and Hénin (1962) have concluded that kaolinite can only ever be formed when the aluminium hydroxide is in the form of gibbsite. Otherwise, the precipitate formed will be a "mixed alumino-silicic gel" (as Millot, 1970, p. 343 put it). If it were the only requirement, large amounts of kaolinite could be harvested simply by adding gibbsite powder to a silica solution. Undoubtedly a marked degree of adsorption of the silica in solution by the gibbsite surfaces will take place, but, as stated before, mere adsorption does not create the layer lattice typical of kaolinite crystals.

The third aspect is that these two initial components must be incorporated into one mixed crystal with a layer structure. From the following equation (as given by Gastuche and DeKimpe, 1962) for kaolinite formation

it can be seen that five molecules of water must be removed from the reaction for every molecule of kaolinite formed. Field evidence illustrating the importance of the removal of water from the kaolinite reaction has been supplied by Gastuche and DeKimpe (1962). While studying soil formation on a basaltic rock in Kivu (Zaïre), they noted how the occurrence of kaolinite depended on the "degrée de drainage" of the area involved. A clear distinction was found between areas with good drainage (i.e., areas with a marked difference between wet and dry seasons) and those areas with poor drainage (i.e., perennially swampy areas). Kaolinite was only found in the areas with distinct seasonal alternations between wet and dry. The possible significance of alternating wet and dry conditions on the transition of allophane into kaolinite has been stressed by Tamura and Jackson (1953). The role of alternations between wetting and drying on the formation of kaolinite has also been noted by Moore (1964).

Laboratory syntheses

Syntheses of kaolinite at high temperatures (more than 100 °C ) are relatively well known. There are for example the syntheses of Van Nieuwenberg and Pieters (1929); Noll (1934); Noll (1936); Norton (1939); Roy and Osborn (1954); Roy (1961); Hawkins and Roy (1962); Tomura et al. (1985); Satokawa et al. (1994) and Huertas et al. (1999). Relatively few low-temperature syntheses have become known (cf. Brindley and DeKimpe (1961); DeKimpe (1969); Bogatyrev et al. (1997)).